BYI

STRIPPING BUSBARS

LEAN Manufacturing

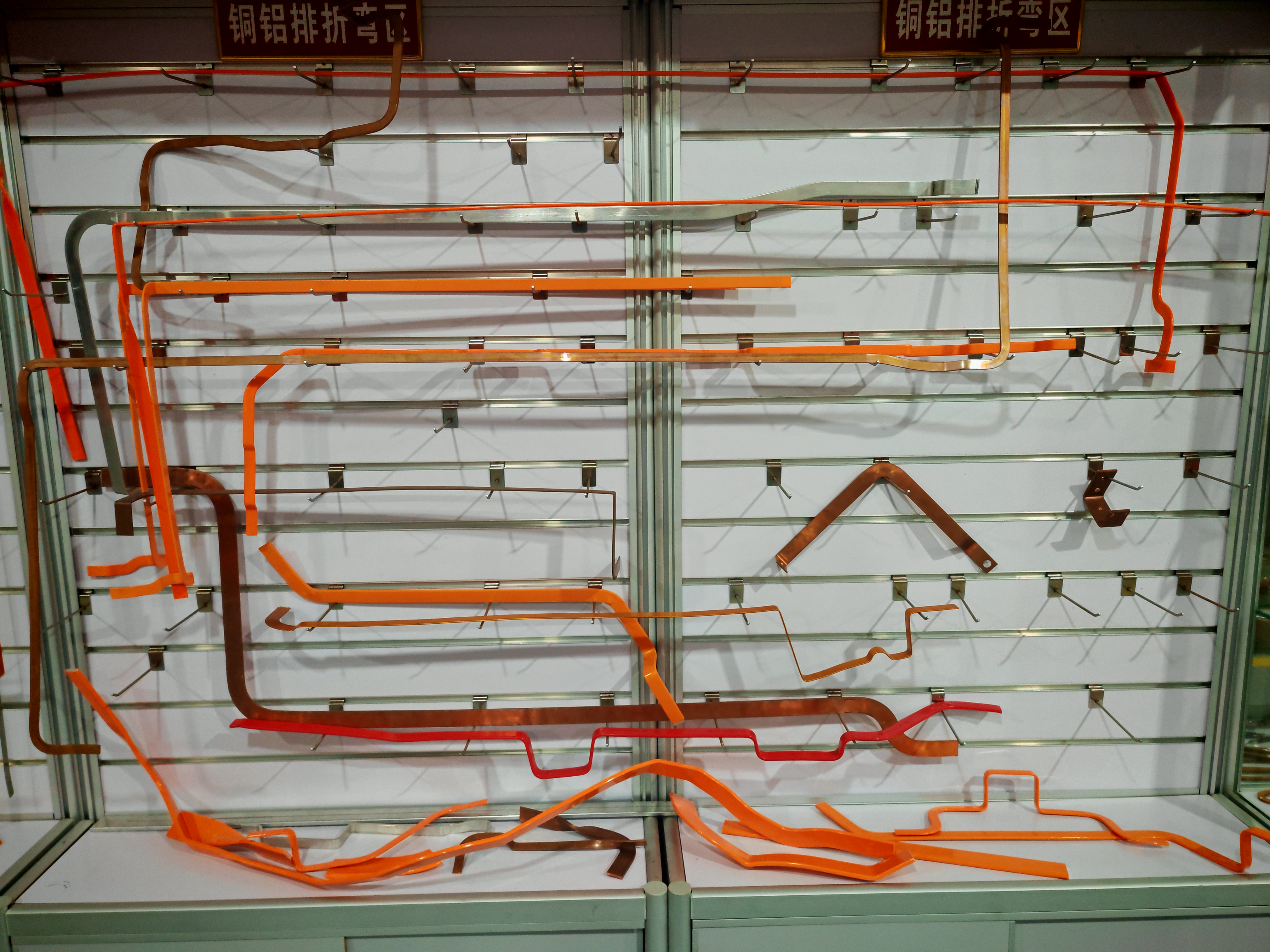

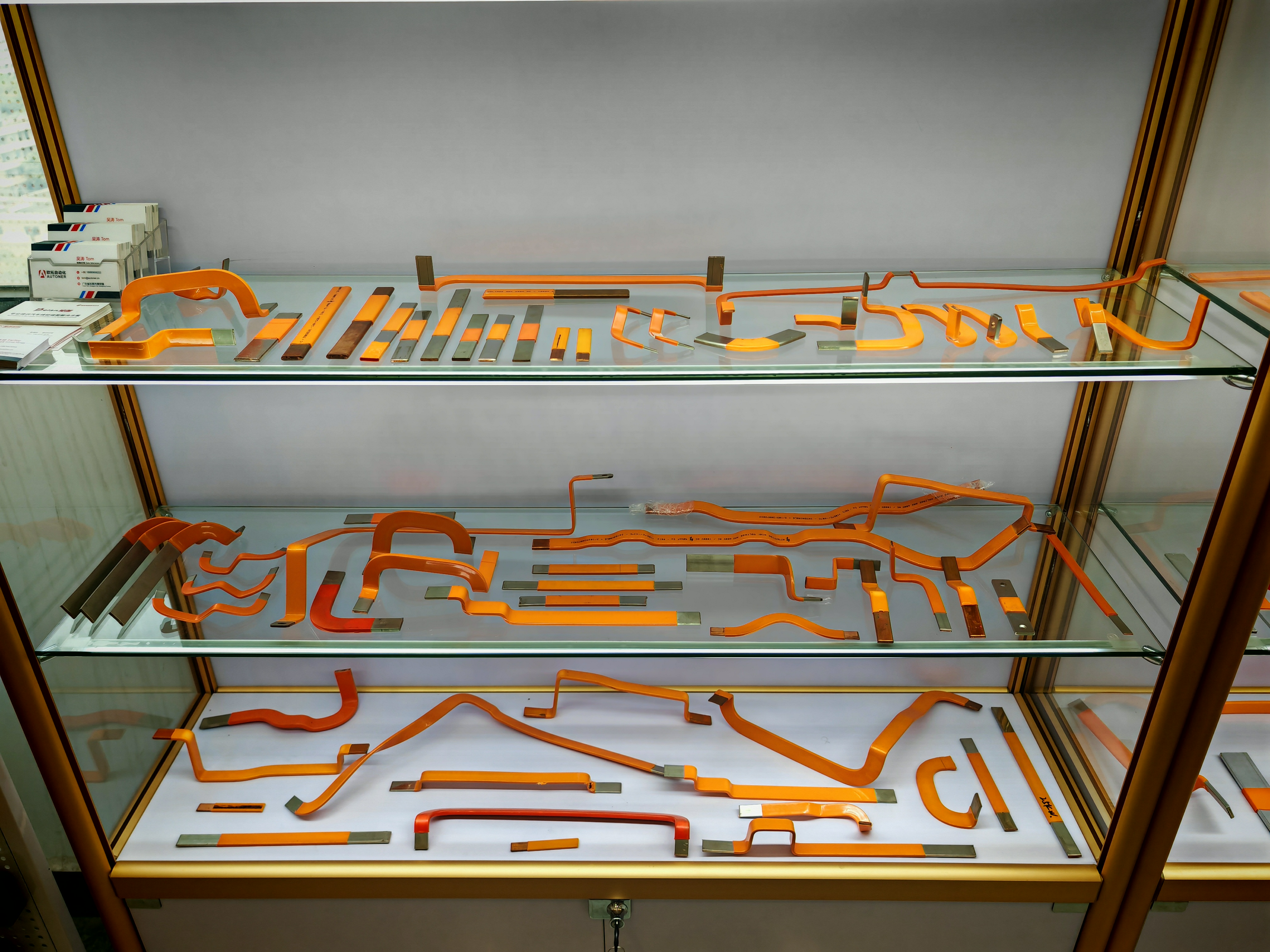

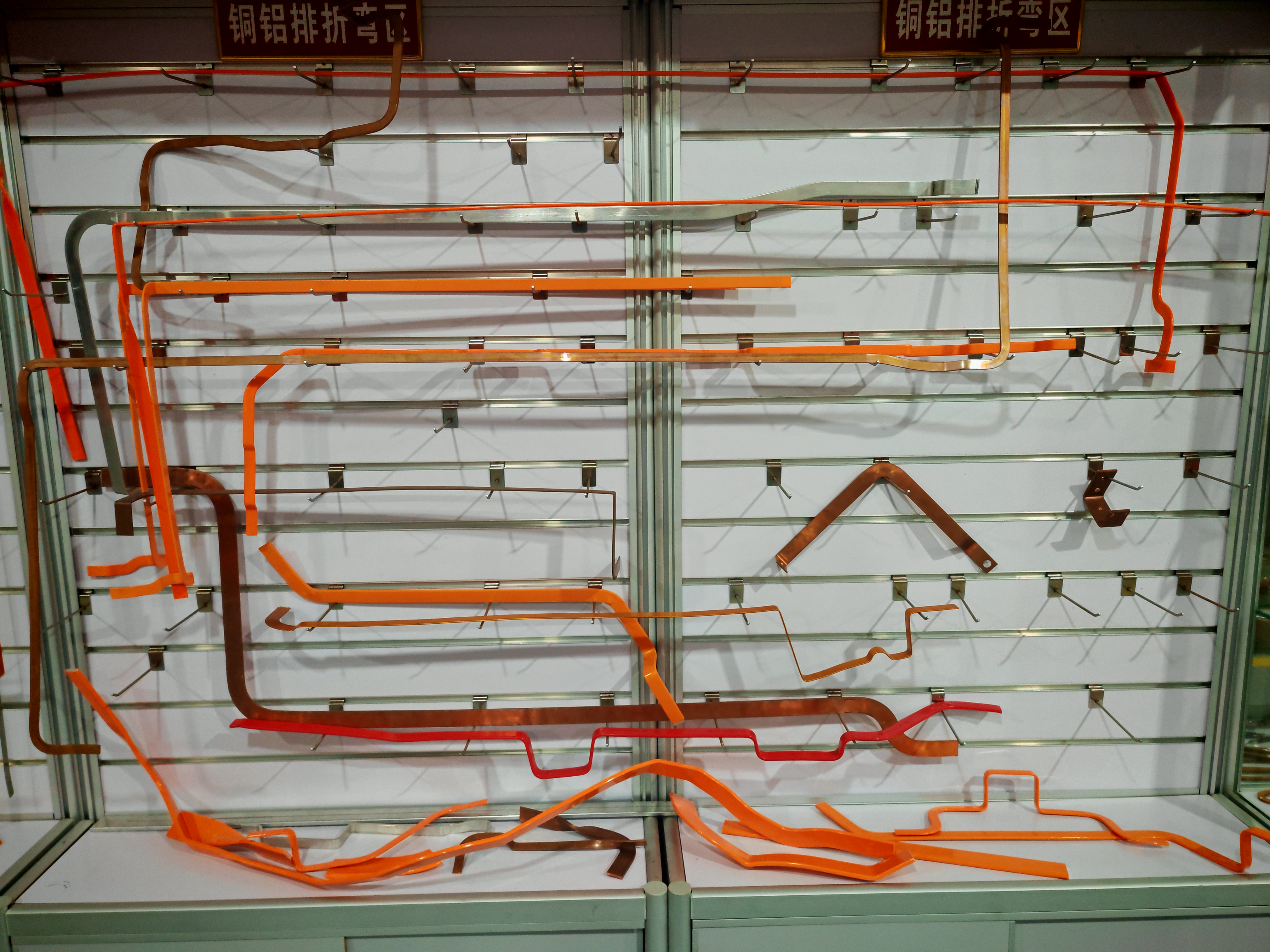

BENDING BUSBARS

INDUSTRIAL CONSULTING

EXTRUSION LINE - Flat cable

BUSINESS STRATEGY

WELDING MACHINES

INJECTION MOLDING

BYI-SOLUTIONS

BENDING Machine Solutions

BENDING -PUNCHING

since 2016

Flat Bending

Twisted Bending

Vertical Bending

Punching

Contact us for your projects and for receive a detailed quotation.

infos@byi-solutions.com

We have a solution for all types of Flat busbars in Copper or Aluminium

With three decades of global experience in the Automotive business, we knows exactly what are important .

Our Rules

We follow our customers in every countries with a smooth and efficient commissioning

Maximize efficiency with expert equipment guidance. and senior specialist .

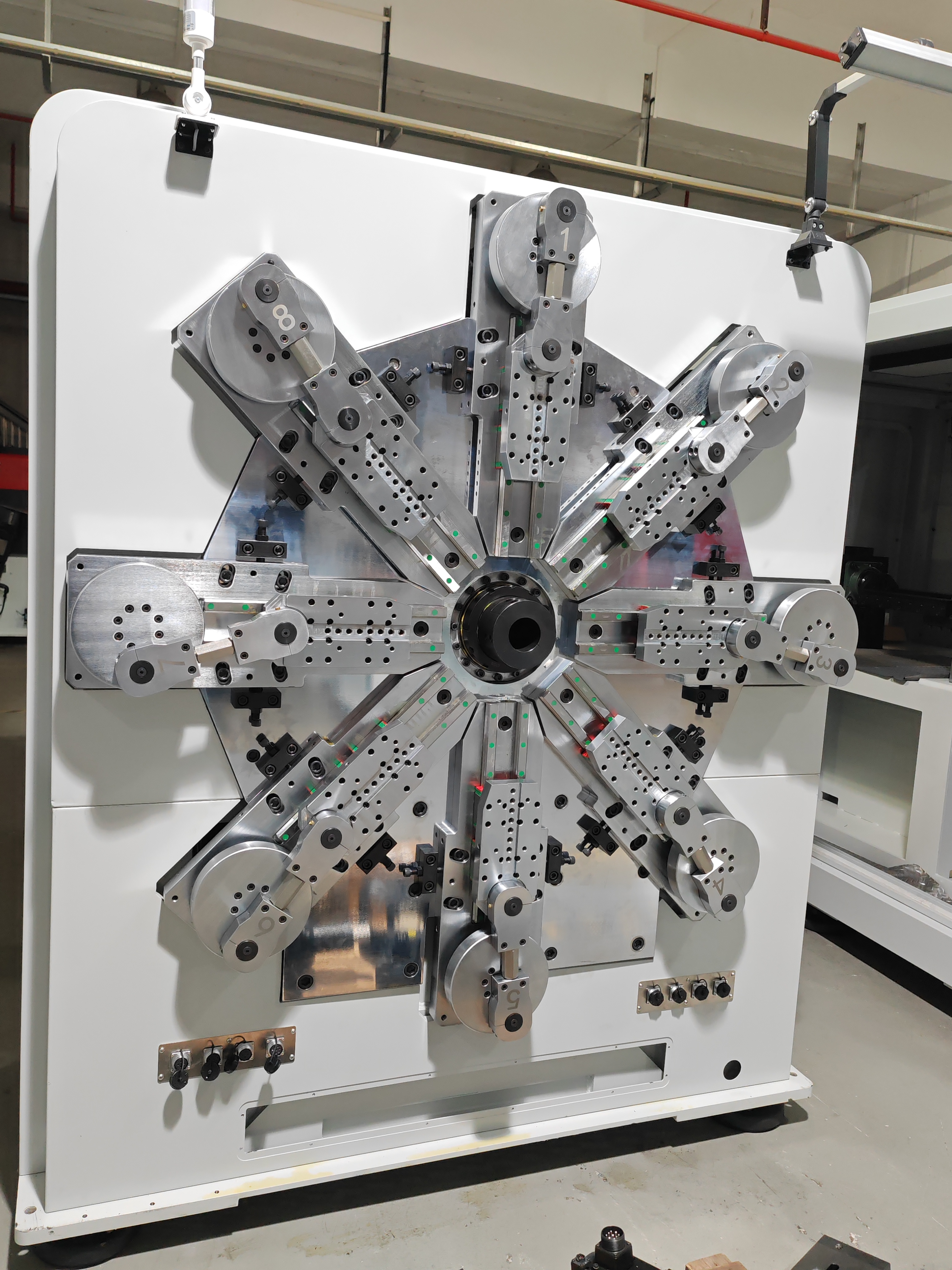

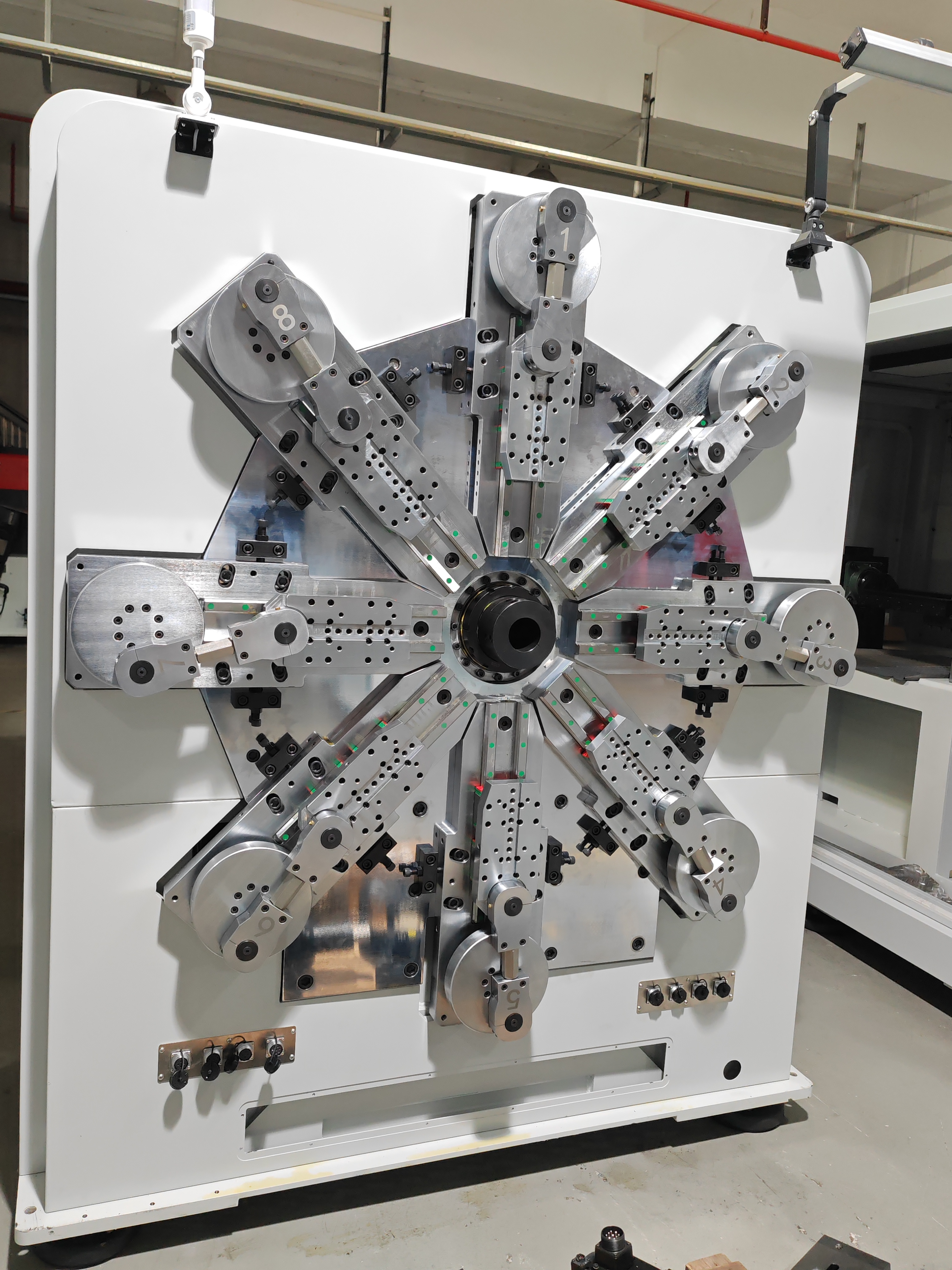

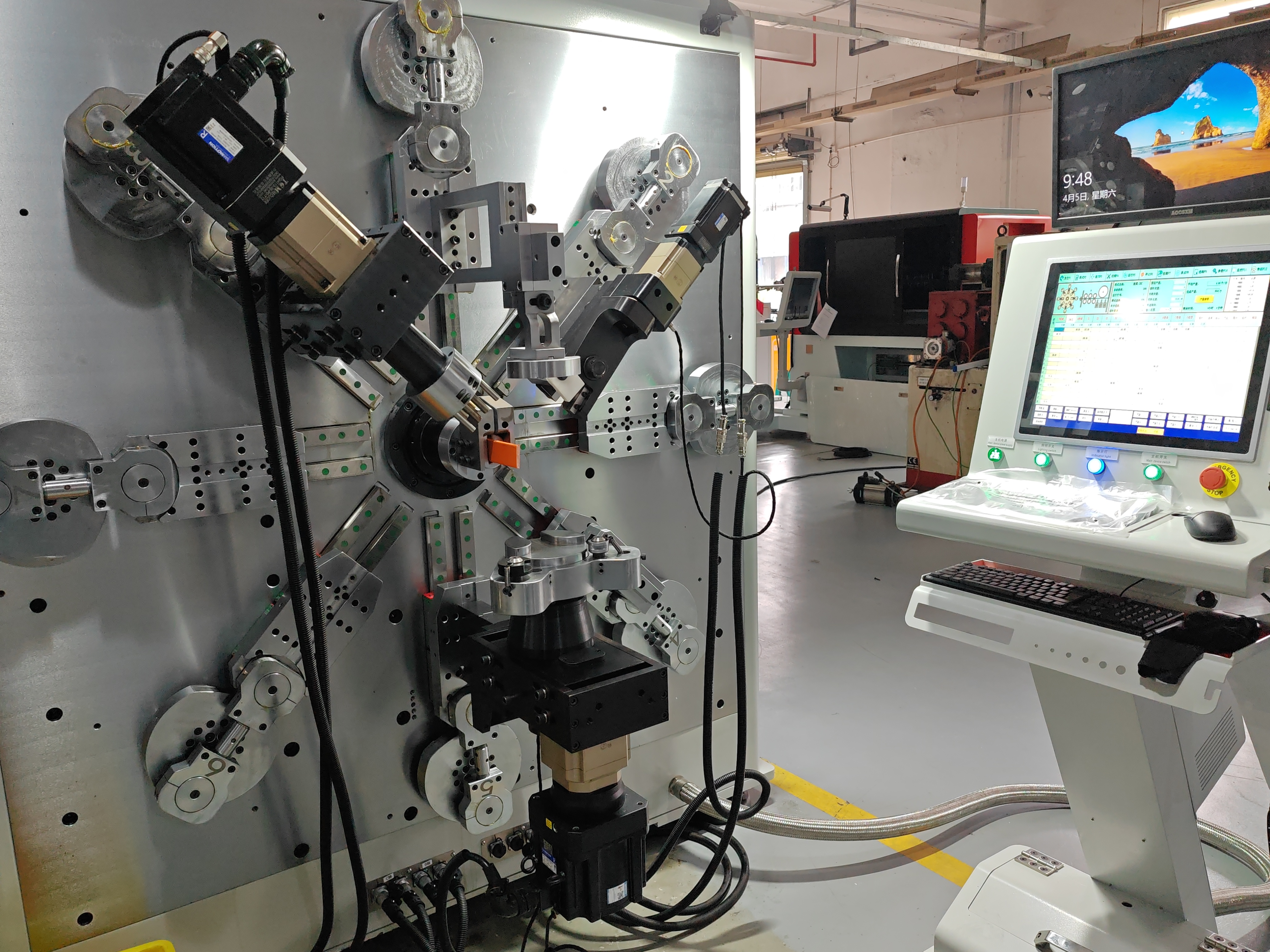

Motorized Bending Machine for Flat Busbars

All-in-one busbar processing: Capable of vertical bending, twisting, flattening, and punching flat busbars in a single machine.

Optimized for e-mobility: Precisely forms EV battery pack busbars, ensuring safe, reliable power connections between battery modules.

Built for power distribution: Bends custom busbar shapes that fit perfectly in electrical panels and switchgear, ensuring seamless integration and reliable connections.

High precision fabrication: Motorized control ensures accurate bends and hole alignment (±1° precision) with smooth, burr-free results.

Efficient & cost-saving: One compact machine handles all tasks, boosting production speed while saving floor space and equipment costs.

Easy & safe operation: Intuitive controls (with foot pedal mode) and emergency-stop safety features allow any operator to use it with minimal training.

Industrial-grade durability: Robust design withstands high loads and continuous use, ideal for demanding factory and workshop environments.

Our Partner produce the bending Machines for flat busbars since 2016

Our CUSTOMERS Panel

WELDING Diffusion Technologies

Diffusion Welding Machines: Advanced Busbar Connectivity

Innovative Precision

Our diffusion welding machines use state‐of‐the‐art technology to join flat copper and aluminum busbars as well as flexible busbars, ensuring a seamless and permanent bond.

Seamless Atomic Bonding

By controlling heat, pressure, and protective gas, the process promotes atomic diffusion across thin foils, yielding high electrical conductivity and mechanical strength.

Optimized Performance

The welding process minimizes thermal deformation and residual stress, securing dimensional accuracy for high-current, high-power applications.

Versatile Applications

Ideal for electric vehicles, energy storage systems, power grids, and industrial automation, our technology delivers robust, low-resistance connections in diverse settings.

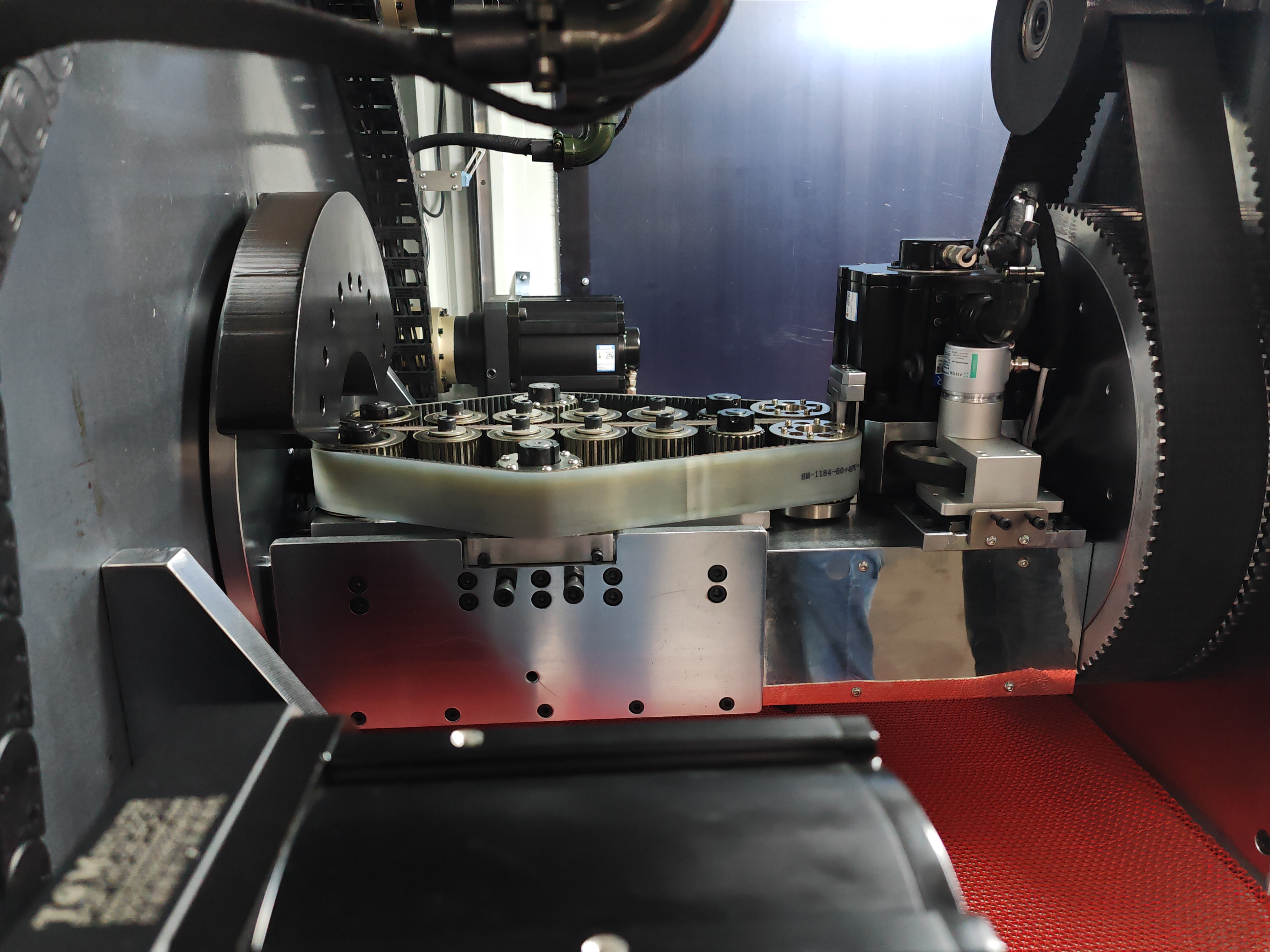

Automated and Customizable

With advanced process control and automatic loading features, production is streamlined while adaptable settings allow for precision welding of both similar and dissimilar materials.

Cost-Effective Reliability

Our diffusion welding solutions lower production costs and improve safety by achieving consistent, high-quality bonds that stand up to rigorous operational demands.

Future-Proof Electrical Systems

Transform your designs with innovative busbar assembly that enhances performance, longevity, and efficiency, powering next-generation energy solutions.

Discover Excellence

Embrace the future of electrical connectivity with our innovative diffusion welding technology—where precision meets reliability for superior busbar performance.

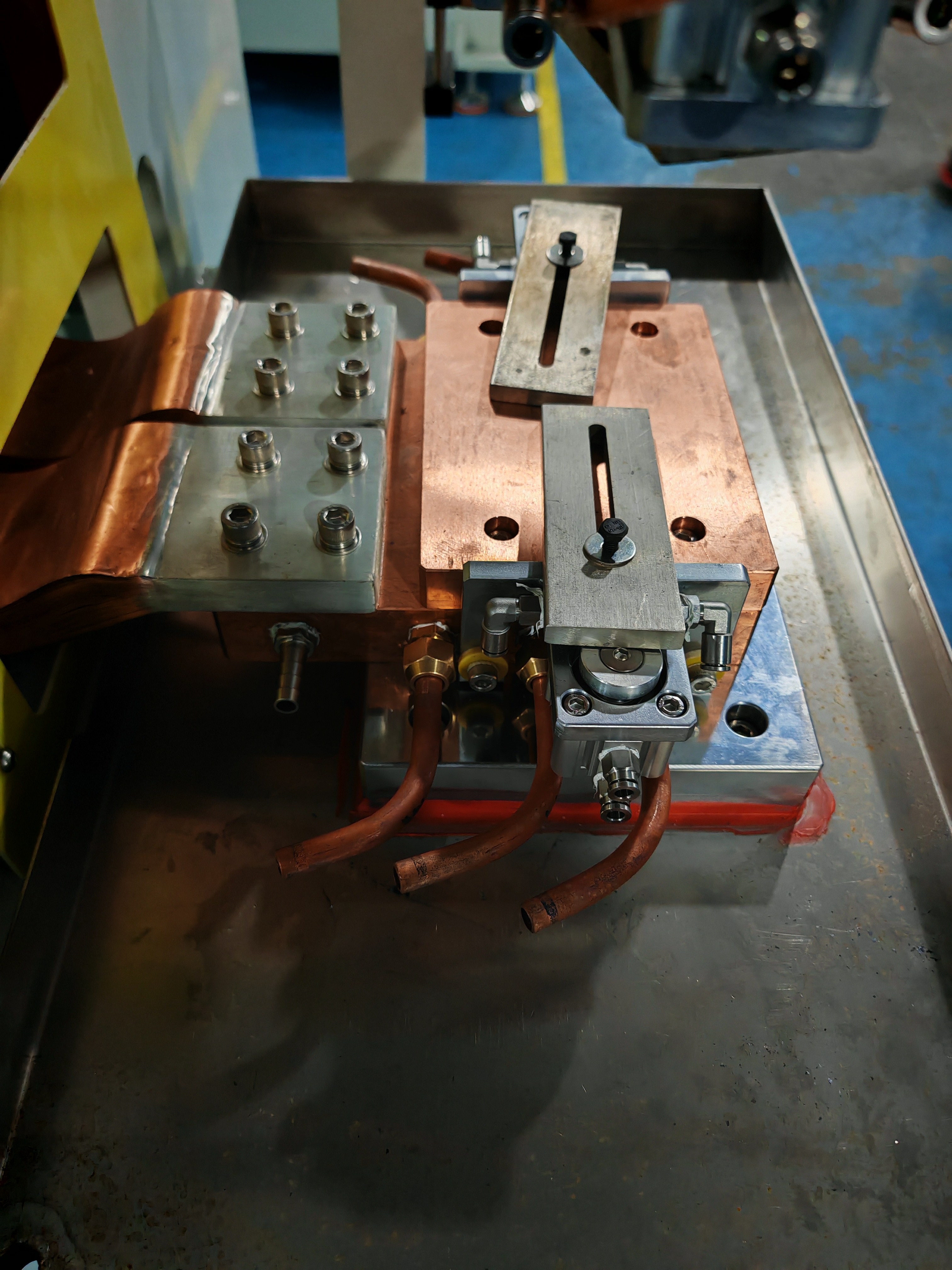

WELDING DIFFUSION Machines Line

ALUMINUM WELDING

Machine

COPPER WELDING Machine

Servo Terminal

WELDING Machine

Automatic Loading & Unloading Mechanism for Welding Diffusion Machine

Rapid Diffusion Welding Machine

with Gas protection

Welding Diffusion for Flexible Busbar

Applications of diffusion welding products: Copper flexible busbars

STRIPPING Machine Solutions

CUSTOMERS PANEL

SHANGHAI 2025 - PRODUCTRONICA CHINA

Mr TOM

AUTONER-CN

SALES Director

Mr HANK

AUTONER-CN

R&D Director

Mr FARLEY

AUTONER-CN

Technical Director

Mr MARIE

AUTONER-SOLUTIONS

European Exclusive Distributor

Copyright © 2066 Codedesign.ai . All Rights Reserved.

Terms of Use

Privacy Policy